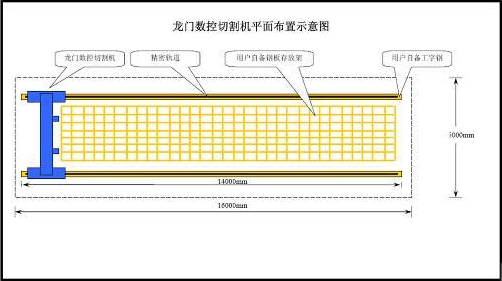

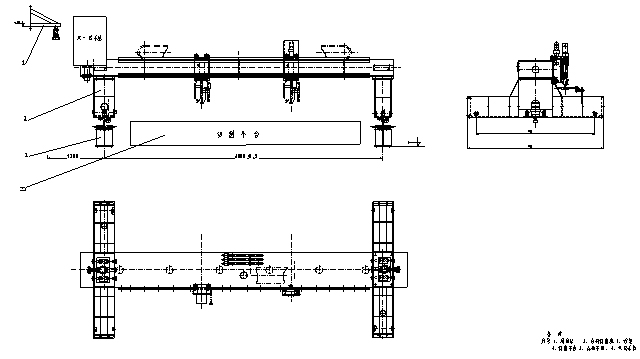

PWGS series CNC cutting machine

Product Overview

● PWGS series CNC plasma/flame cutting machine is a high-efficiency steel plate automatic cutting and blanking equipment developed by our company for the processing of metal structural parts. Cutting surface roughness and high precision, small deformation. The machine has the advantages of reasonable structure and simple operation.

● The components of this series of CNC cutting machines include CNC system, drive system, control system, mechanical transmission system, and pneumatic cutting system. This machine is mainly used for flame and plasma dual-purpose cutting of various shapes of metal sheet planes. It has complete functions, high degree of automation, professional configuration, high cutting precision, good cutting quality and good dynamic stability. CNC system and servo system adopt excellent performance, convenient man-machine interface, simple operation, rich software and high-quality hardware configuration, and comprehensive protection measures to provide users with a high-quality product.